"Information is key to improving performance,

reducing downtime and expanding asset live time."

Even if you think your operation can't get more efficient, there is still a lot to gain. Because data accumulates over time, you will learn more and more about your system behaviour and find possibilities to optimize.

Technology will progress, new posibilities to enhance efficiency, quality and capacbillities will increase.

Your machine, factory and resources are in a constant race, to stay a head of competition data plays a crucial role.

Welcome to the next generation of manufacturing analytics. Maximize asset uptime and increase capacity.

Connect to virtually any CNC machines and extract all operating data to be used in analysis and scheduling applications.

In combination with our Asset Management software OpenICM we will be able to analyse, optimize and shedule machines.

An elaborate solution for mid size companies (>40 CNC machines) that need to increase OEE and have a Continouse improvement plan in place.

With SmartFactory, your employees, machines and processes in your business can be controlled from a single center. It is designed to provide you with all the technological requirements your business needs and allows you to access all the data you need in seconds with advanced reporting options.Download free demo

The most easily realized effectiveness measure is OEE (Overall Equipment Effectiveness). You measure downtime, production time and capacity.

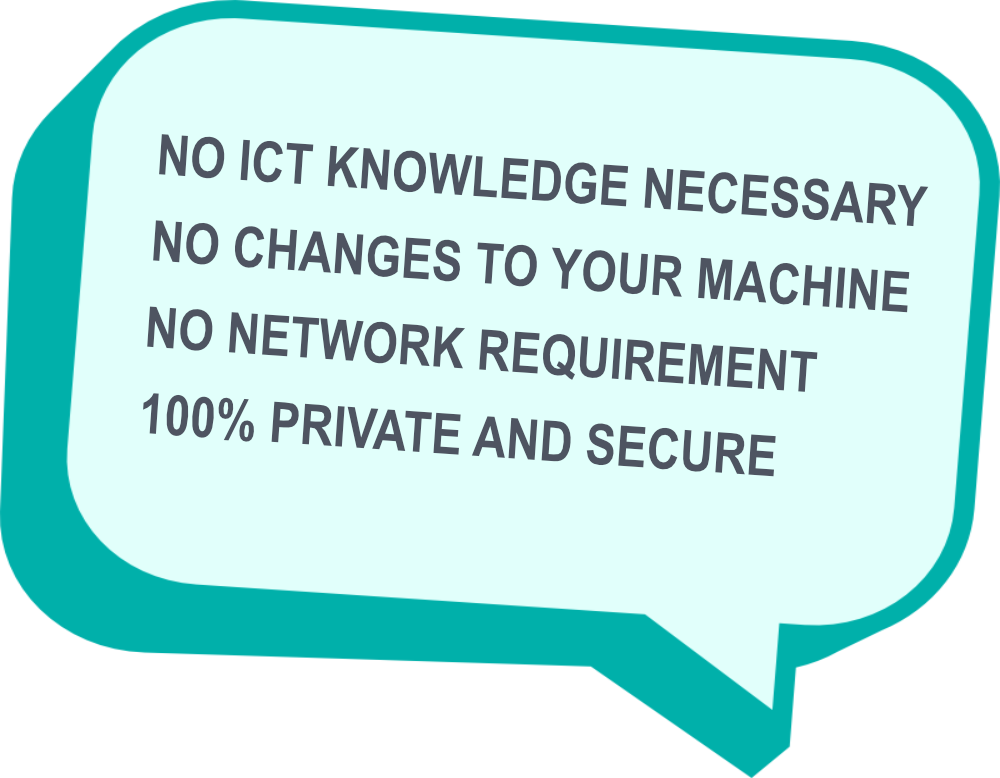

Measure OEE easily and without modifications to your existing plant with our OEE sensor kit.

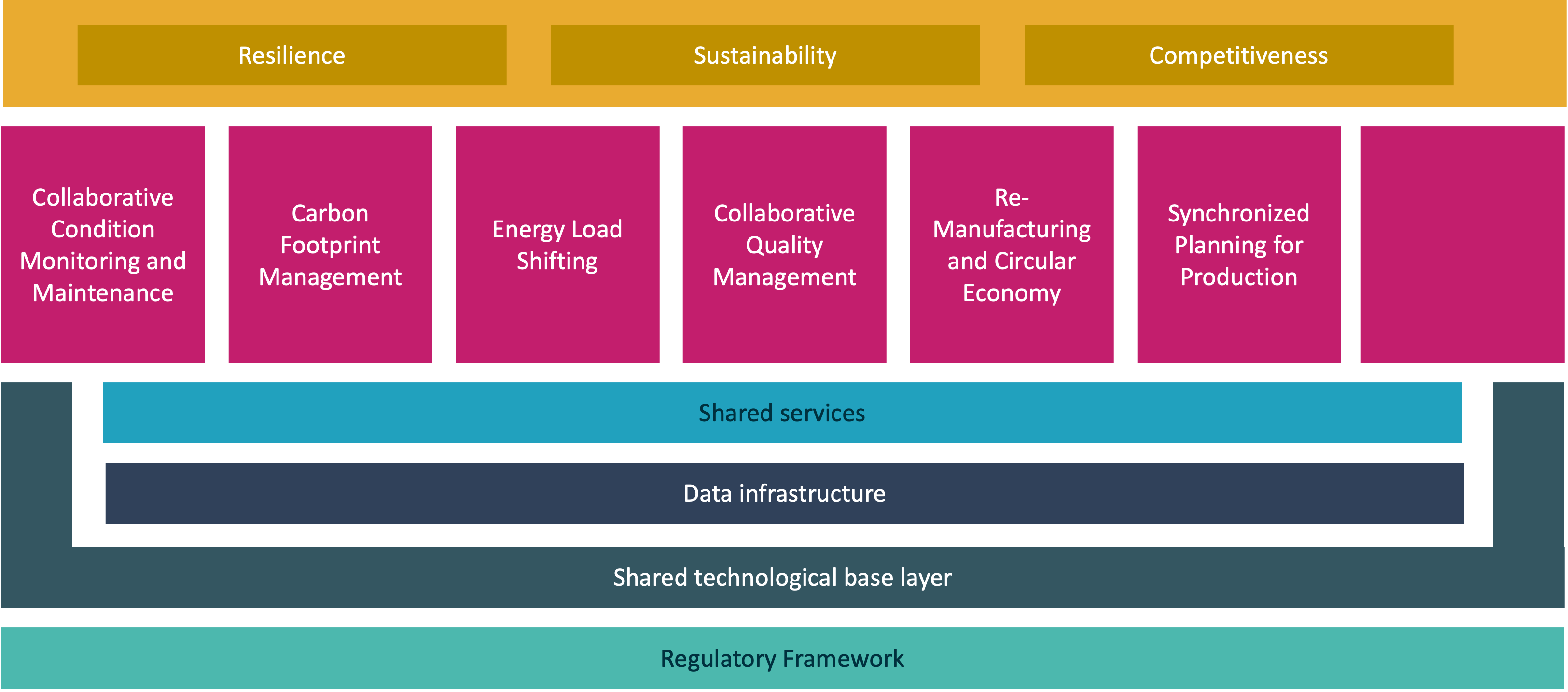

Collaboration and sharing data throughout the entire creation and maintenance chain is essential for a resiliant and effective operation. OpenICM offerts all functions to enable data driven chain collaboration.

Connect IIoT EDGE devices and PLC's without the hassle of software installation via our SaaS solution or have OpenICM running on one of your servers. Users will access via a standard webbrowser on a desktop, tablet or smartphone.

Engineering

Engineering(p/m/user)

Standard

Standard(p/m/user)

SaaS

SaaS(p/m/user)

Onprimise

Onprimise(p/m/user)

We know maintenance personal won't and cannot be missed for days in a row, that's why we provide a railroad schedule to learn OpenICM and predictive maintenance step-by-step in a modern online and interactive way. Select which learning path suites best.

Opting for OpenICM / a modern maintenance application ECO system introduces new technologies and possibilities. Our service and support team will be @ your side to setup your maintenance and help to gain the most out of OpenICM.

Practical advise and help to choose your best advanced maintenance strategy.

Technical support in every aspect, from complete setup of your SMART maintenance to a helping hand and guidance.

Learn more..SENSOR TECHNOLOGY | PREDICTIVE MAINTENANCE | OPERATIONAL EXCELLENCE

We use functional cookies but do not sell or use your browsing history nor do we use cookies from other (social) websites. Your data is save with us.